On this page you find the history of the origin of the "Elvis: Born To Rock" book. Be part of this exciting process by stepping through the following pages. Because of the large amount of data, the producers decided to split this "Making Of" into several parts. By the end of each part you have the possibility to step directly into the corresponding image gallery.

The producers hope that you will like this "Making Of" and have a great time surfing the pages.

In The Beginning there was an idea ...

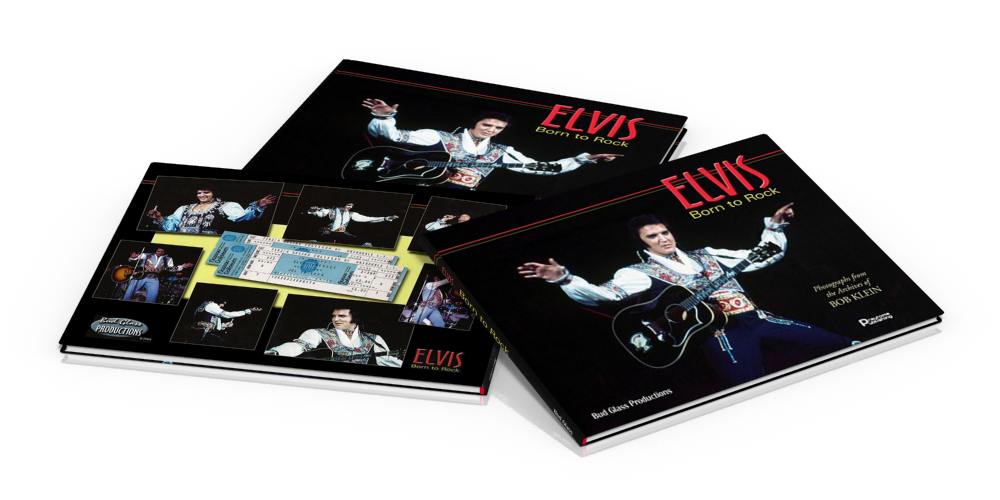

Back in 2002 during the editor conference, the decision was made that the second book should definitely be a different genre. While the first book "Elvis: Behind The Image - The Book", which dealed exclusively with the private Elvis - under the use of phenomenal candid pictures - the producers now wanted to dedicate their next release to the Entertainer: Elvis Presley - live on stage.

After intensive research and months full of exciting work, Bud Glass began with the composition and the layout of the book so that, slowly but surely, the project started to gain ground.

During these works Bud Glass Productions received additional information and pictures the author absolutely wanted to use in his book. This explains, among other things, why a product can't be developed within 4 weeks. The self-set high quality standards (not a single picture on a single page and call it a book) caused the high expenditure of time. To create a design which is not only tasty but also stylistically fitting the 70's, to scan old original pictures and to edit them with the newest technology doesn't only require the according Know-How, but also the necessary preconditions.

Even though we had the great luck to be able to fall back on the original negatives, a lot of work remained to transfer the pictures and their magnificent colours into the final book.

The producers took painstaking care of keeping the information to be included in the book professionally up-to-date, so that several editors were put in charge of supporting Bud Glass Productions.

All these apsects caused a delay so that it quickly became clear that this huge project with its numerous unpublished colour pictures and detailed information could not be done within the self-set schedule.

It had been the right decision to produce the first product in Europe, Praytome Publishing decided quickly to assign a German print office with the production of "Elvis: Born To Rock". That this experience would pay off quickly became clear and the possibility to keep an eye the production daily to be able to intervene immediately in upcoming mistakes, also proved to be invaluable.

The great reactions on the "Making Of" book trailer of "BTI - The Book", the enthusiastic mails concerning the "Creation Of Dreams" Making of "Elvis: Adrenaline '70" showed the producers clearly, that the fans are not only interested in Elvis himself, but that the bonus features were also very welcomed very positively.

So Praytome Publishing is happy to be able to allow another insight into its latest project.

The following pictures are not only giving you the possibility to get an insight into the development of Born To Rock, but you can also watch the progression because this "Making Of" the "Born To Rock" book will be updated continuously. Visit this site to watch the latest progress and to be there when we are able to say: The book is completed!

When the author has finished his work on the book, another long process begins - with breakpoints at lithographers, print offices and layout experts - for reaching the final goal: The completition of the book.

Right here the following "Making Of" starts:

-

Making Of "Born To Rock" Part 1 - Images 1- 10

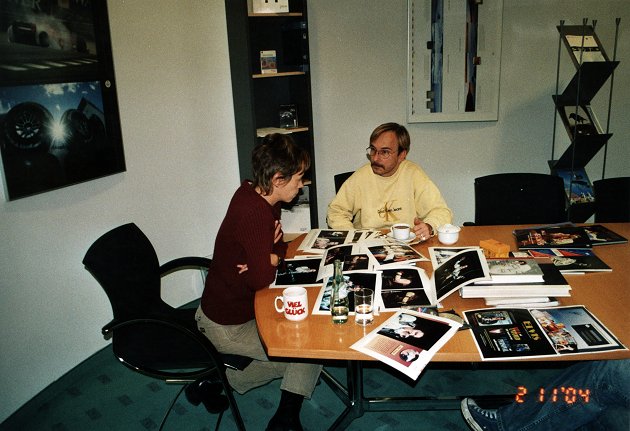

Nadine Schwenk, Claudia Hainsch, Greg Retkowski (f.l.t.r.)In daily conferences with the according experts every single aspect of the book is discussed.

Nadine Schwenk, Claudia Hainsch, Greg Retkowski (f.l.t.r.)In daily conferences with the according experts every single aspect of the book is discussed.

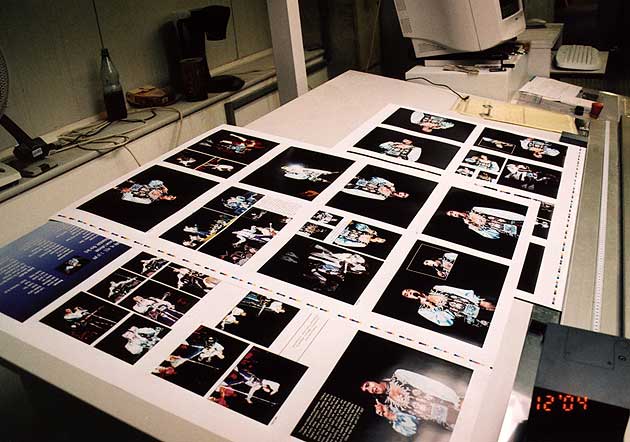

After the first examinations of the samples the producers decided to go the expensive and complex way and to undergo every single page a so called "proof" procedure.

After the first examinations of the samples the producers decided to go the expensive and complex way and to undergo every single page a so called "proof" procedure.

A "proof" ties up to an 98% image of the estimated print result. Hereby you can see the resultant color shifts and you are able to detect errors and flaws within the pictures to correct them before the final print.After the first examinations of the samples the producers decided to go the expensive and complex way and to undergo every single page a so called "proof" procedure.

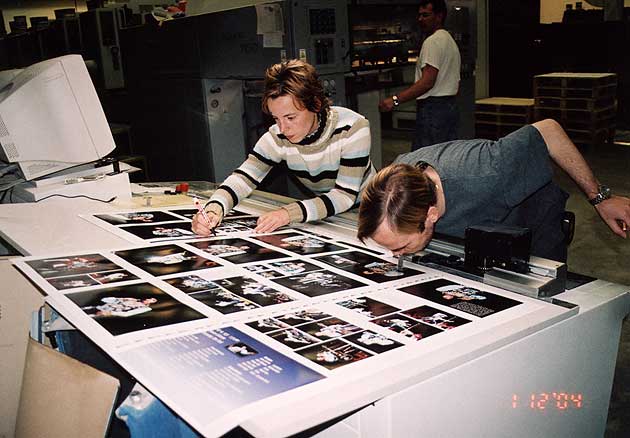

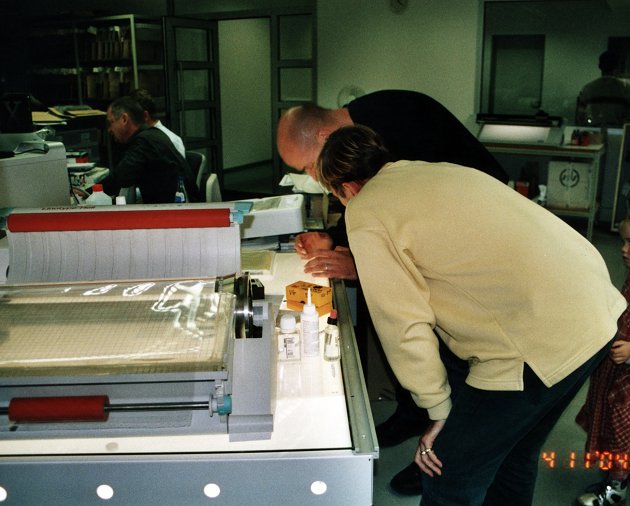

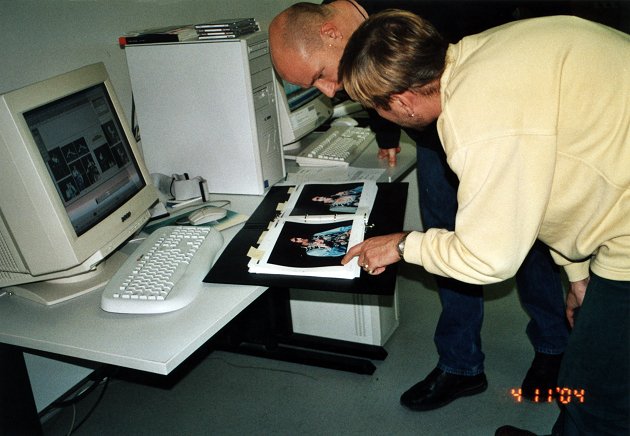

A "proof" ties up to an 98% image of the estimated print result. Hereby you can see the resultant color shifts and you are able to detect errors and flaws within the pictures to correct them before the final print.Lithographer Markus Müller and Praytome during controls at the light table.

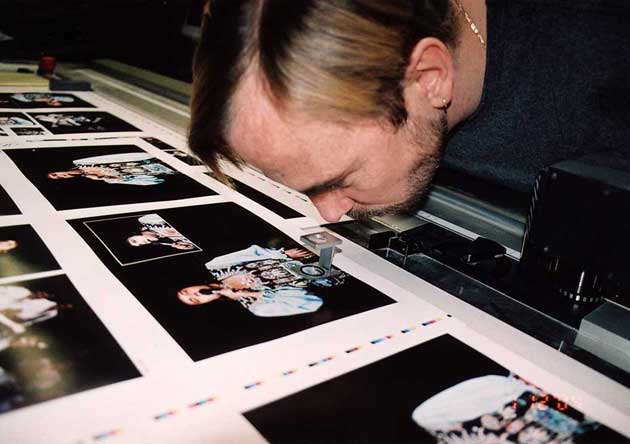

If mistakes are noticed the lithographer can analyze and judge how the mistake in the original file can be corrected in the best way because of his professional competence and his equipment.

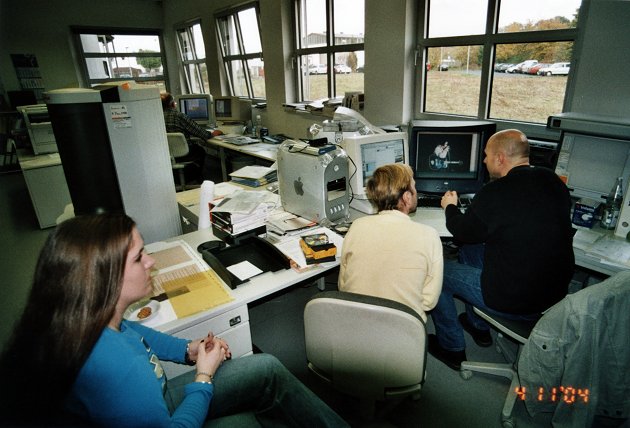

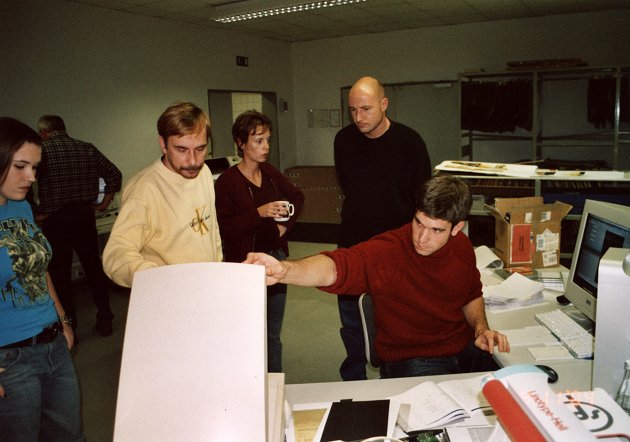

Nadine Schwenk, Praytome and lithographer Markus Müller during the correcting process at the workstation.After every correction it is necessary to create a new proof to control the changes.

Nadine Schwenk, Praytome and lithographer Markus Müller during the correcting process at the workstation.After every correction it is necessary to create a new proof to control the changes.

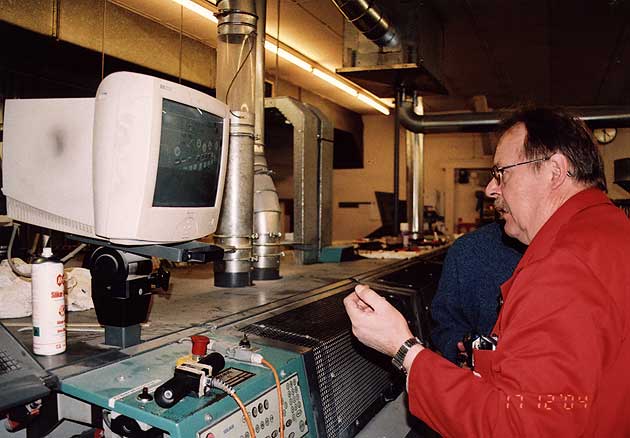

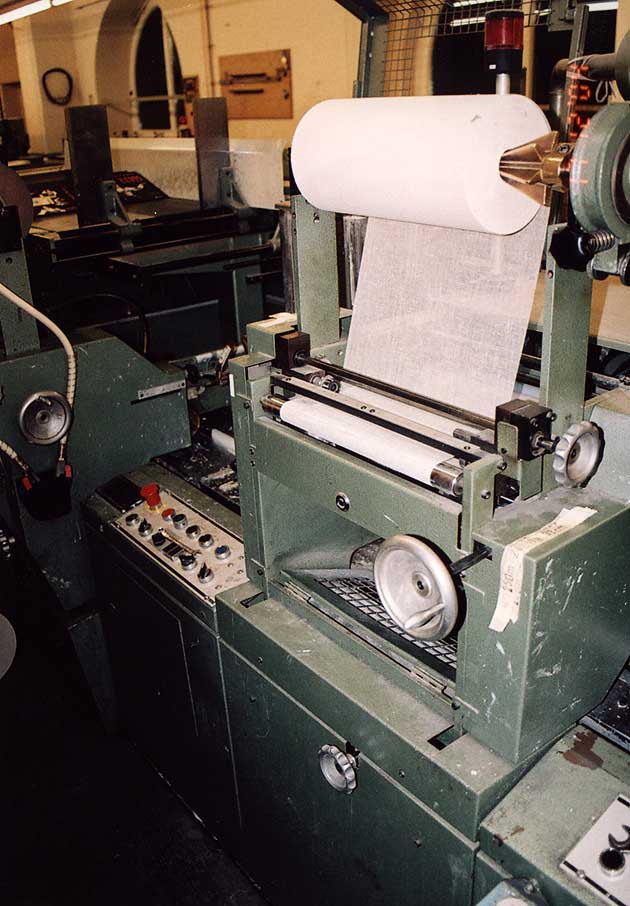

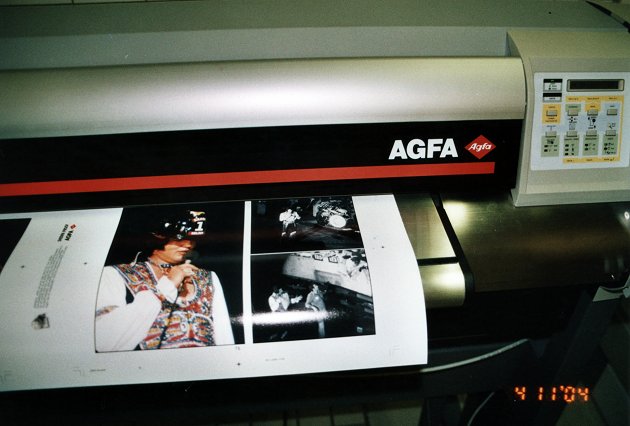

By doing several scan procedures color depths are being detected to get an optimum result in the print.

By doing several scan procedures color depths are being detected to get an optimum result in the print.

You can see clearly how many persons are involved in the realization. Competence and equipment, which is shown here, make clear that "Born To Rock" is not a home-made production.By doing several scan procedures color depths are being detected to get an optimum result in the print.

You can see clearly how many persons are involved in the realization. Competence and equipment, which is shown here, make clear that "Born To Rock" is not a home-made production.The "Plotter" room.

The plotter at work.The proof being nearly complete.

The plotter at work.The proof being nearly complete.

We'd like to take this opportunity to thank the many people who have contributed to this project and the actual progress of the "Born To Rock" book. Those fans who have supported us with pictures, concert reviews and their invaluable memories of the concerts and the competent and friendly employees at the Dassel Druck GmbH, who helped us so much with the printing work.

-

Making Of "Born To Rock" Part 2 - Printer Images 1-17

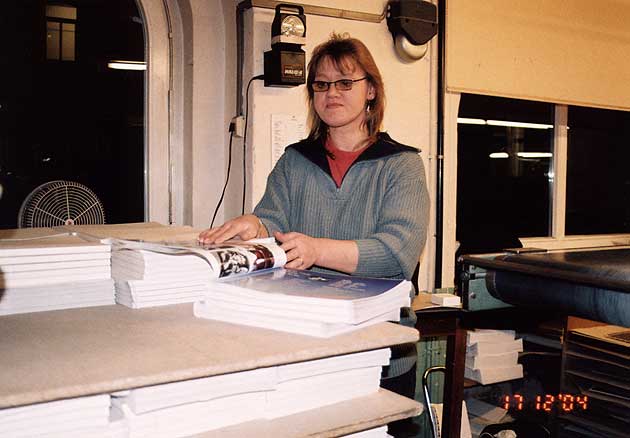

After many months of long work and intensive post-editing which is necessary when doing such a complex project, the actual printing process is imminent now.Claudia Hainsch and Eva-Katharina Retkowski

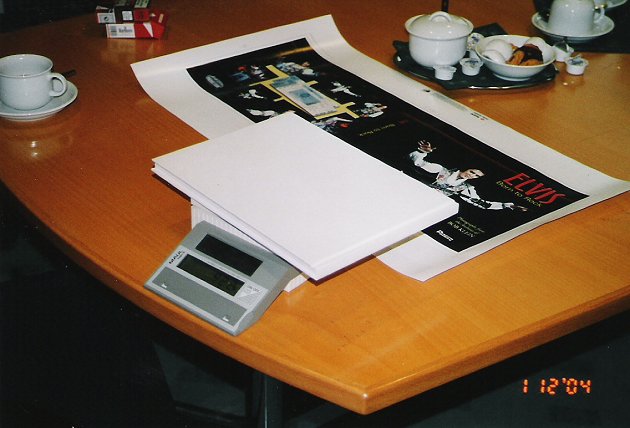

Here you can see the last minute checks and the last conference just before the book goes to the printing company. Mrs. Retkowski (Behind-The-Image Team) holds a plain book in her hands which doesn't only contain the dimensions and the kind / thickness of the paper but it has also the amount of pages inside so one can calculate the terminal weight.

Here you can see the last minute checks and the last conference just before the book goes to the printing company. Mrs. Retkowski (Behind-The-Image Team) holds a plain book in her hands which doesn't only contain the dimensions and the kind / thickness of the paper but it has also the amount of pages inside so one can calculate the terminal weight.

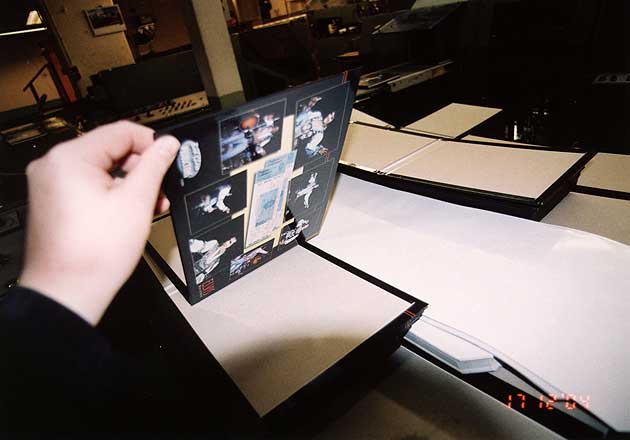

For the first time you can see the proof being the cover later with front and back side as well as the spine.Here you can see the last minute checks and the last conference just before the book goes to the printing company. Mrs. Retkowski (Behind-The-Image Team) holds a plain book in her hands which doesn't only contain the dimensions and the kind / thickness of the paper but it has also the amount of pages inside so one can calculate the terminal weight.

For the first time you can see the proof being the cover later with front and back side as well as the spine.It is clearly noticeable that "Elvis: Born To Rock" has the unusual landscape format, which was chosen to stand out from other projects. The main reason for this format is the fact that most stage pictures were also taken in landscape format. And if you want to display these pictures in a large size, this isn't possible in a panel format.

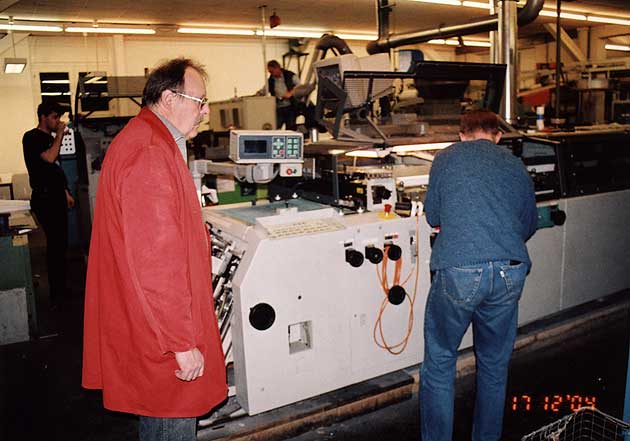

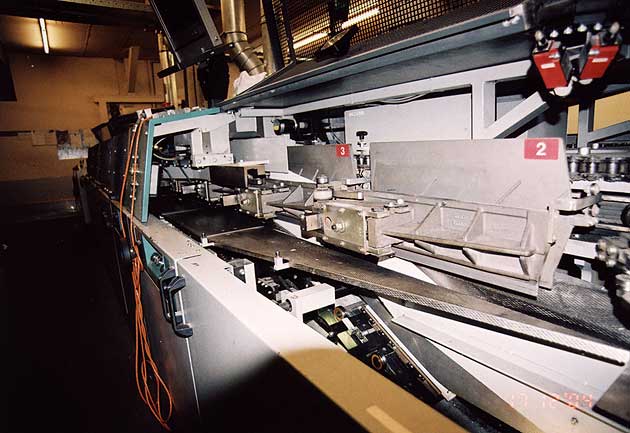

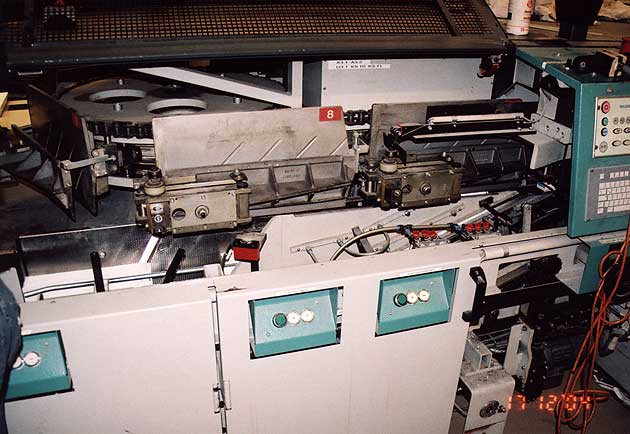

So the producers are able to say, that "Elvis: Born To Rock" is the first wide screen book in the Elvis history.As you can see here on the scale the book will have a total weight of nearly 1 kg. To the 922 g the weights of colour and cover have to be added. While Praytome Publishing Products are sold all over the world the weight of the book is a very important information. The weight influences the shipping costs, for the dealer, which he has to pay later - depending on his residence.As you can see here on the scale the book will have a total weight of nearly 1 kg. To the 922 g the weights of colour and cover have to be added. While Praytome Publishing Products are sold all over the world the weight of the book is a very important information. The weight influences the shipping costs, for the dealer, which he has to pay later - depending on his residence.A big challenge is the walk on the tightrope, the producers are committed to when they have to make the decision for high quality heavy paper; while the producers want to include and share with the fans as many information and pictures as possible, they have to care for the resulting weight - increasing with the number of the pages - which also causes higher shipping costs. A big challenge is the walk on the tightrope, the producers are committed to when they have to make the decision for high quality heavy paper; while the producers want to include and share with the fans as many information and pictures as possible, they have to care for the resulting weight - increasing with the number of the pages - which also causes higher shipping costs.A first look into the hall of the printer doesn't only give the impression of a different world, but the plain of 2 soccer fields is filled with numerous modern machines which will later do the printing. The company Dassel Druck GmbH can be proud of its modern technical machinery.A first look into the hall of the printer doesn't only give the impression of a different world, but the plain of 2 soccer fields is filled with numerous modern machines which will later do the printing. The company Dassel Druck GmbH can be proud of its modern technical machinery.Claudia Hainsch and Markus Vogel (f.l.t.r.). As during the production of their DVDs the producers always try to be up to date concerning the technology and its possibilities and to use them for their new products. On the picture above you can see a desk, which allows a direct interference into the current printing process and controls the tones as well as contrast / saturation changes.

A big challenge is the walk on the tightrope, the producers are committed to when they have to make the decision for high quality heavy paper; while the producers want to include and share with the fans as many information and pictures as possible, they have to care for the resulting weight - increasing with the number of the pages - which also causes higher shipping costs.A first look into the hall of the printer doesn't only give the impression of a different world, but the plain of 2 soccer fields is filled with numerous modern machines which will later do the printing. The company Dassel Druck GmbH can be proud of its modern technical machinery.A first look into the hall of the printer doesn't only give the impression of a different world, but the plain of 2 soccer fields is filled with numerous modern machines which will later do the printing. The company Dassel Druck GmbH can be proud of its modern technical machinery.Claudia Hainsch and Markus Vogel (f.l.t.r.). As during the production of their DVDs the producers always try to be up to date concerning the technology and its possibilities and to use them for their new products. On the picture above you can see a desk, which allows a direct interference into the current printing process and controls the tones as well as contrast / saturation changes. Claudia Hainsch and Markus Vogel (f.l.t.r.). As during the production of their DVDs the producers always try to be up to date concerning the technology and its possibilities and to use them for their new products. On the picture above you can see a desk, which allows a direct interference into the current printing process and controls the tones as well as contrast / saturation changes.Markus Vogel and Klaus Drinhaus control the current processes (f.l.t.r.).

Claudia Hainsch and Markus Vogel (f.l.t.r.). As during the production of their DVDs the producers always try to be up to date concerning the technology and its possibilities and to use them for their new products. On the picture above you can see a desk, which allows a direct interference into the current printing process and controls the tones as well as contrast / saturation changes.Markus Vogel and Klaus Drinhaus control the current processes (f.l.t.r.).

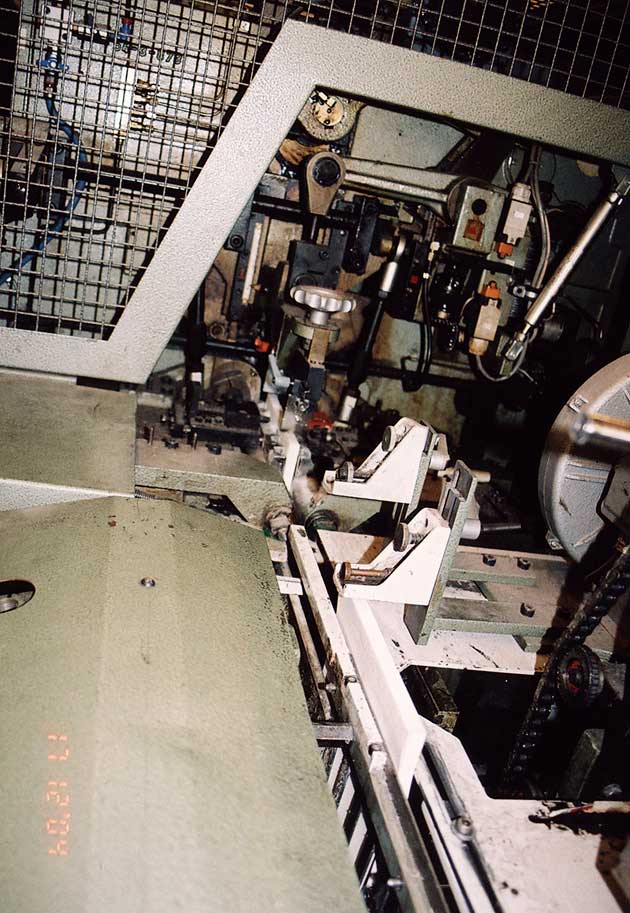

The main machine, as big as a bus. This model is the latest on the market, so the expectations of the producers are already very high in the run-up. The tension to be able to hold the own book at the end of the process in the hands is unbearable.The main machine from the side view. To allow maintenance and control works, stairs with bars were added that the outstanding size isn't such a big obstacle.

The main machine, as big as a bus. This model is the latest on the market, so the expectations of the producers are already very high in the run-up. The tension to be able to hold the own book at the end of the process in the hands is unbearable.The main machine from the side view. To allow maintenance and control works, stairs with bars were added that the outstanding size isn't such a big obstacle.

A view from the top of the machine. Here you can see the apparatus which will hold the certain printing plates and control the colour roles.A printing plate including all the information needed for the machine. So it can be calculated automatically where which colour develops. The basic information for the proportion of mixture is included on the plate. The above shown desk allows the interference into this proportion of mixture.A printing plate including all the information needed for the machine. So it can be calculated automatically where which colour develops. The basic information for the proportion of mixture is included on the plate. The above shown desk allows the interference into this proportion of mixture.

A view from the top of the machine. Here you can see the apparatus which will hold the certain printing plates and control the colour roles.A printing plate including all the information needed for the machine. So it can be calculated automatically where which colour develops. The basic information for the proportion of mixture is included on the plate. The above shown desk allows the interference into this proportion of mixture.A printing plate including all the information needed for the machine. So it can be calculated automatically where which colour develops. The basic information for the proportion of mixture is included on the plate. The above shown desk allows the interference into this proportion of mixture. A view into the main machine from the opposite side. In the foreground you can see clearly the certain printing plates as well as the colour roles.The RGB procedure is not used for the printing of books. (RGB= Red-Yellow-Blue) It is only used for technical machines which have an own luminance like i.e. Computer screens or TVs.

A view into the main machine from the opposite side. In the foreground you can see clearly the certain printing plates as well as the colour roles.The RGB procedure is not used for the printing of books. (RGB= Red-Yellow-Blue) It is only used for technical machines which have an own luminance like i.e. Computer screens or TVs.

A sheet like in the book doesn't have a luminance. The colours develop from a light reflection of an external source, what means from the daylight of the sun or a bulb.You surely know the effect that colours seem different in daylight than in bulb light. To get a certain basic color on the sheet a procedure was developed which counteracts the phenomenon of the absent own luminance: CMYK (= Cyan, Magenta, Yellow, Black).

A sheet like in the book doesn't have a luminance. The colours develop from a light reflection of an external source, what means from the daylight of the sun or a bulb.You surely know the effect that colours seem different in daylight than in bulb light. To get a certain basic color on the sheet a procedure was developed which counteracts the phenomenon of the absent own luminance: CMYK (= Cyan, Magenta, Yellow, Black).

So the used colour management requires 4 different basic colors.

So the used colour management requires 4 different basic colors. -

Making Of "Born To Rock" Part 2 - Printer Images 18-32

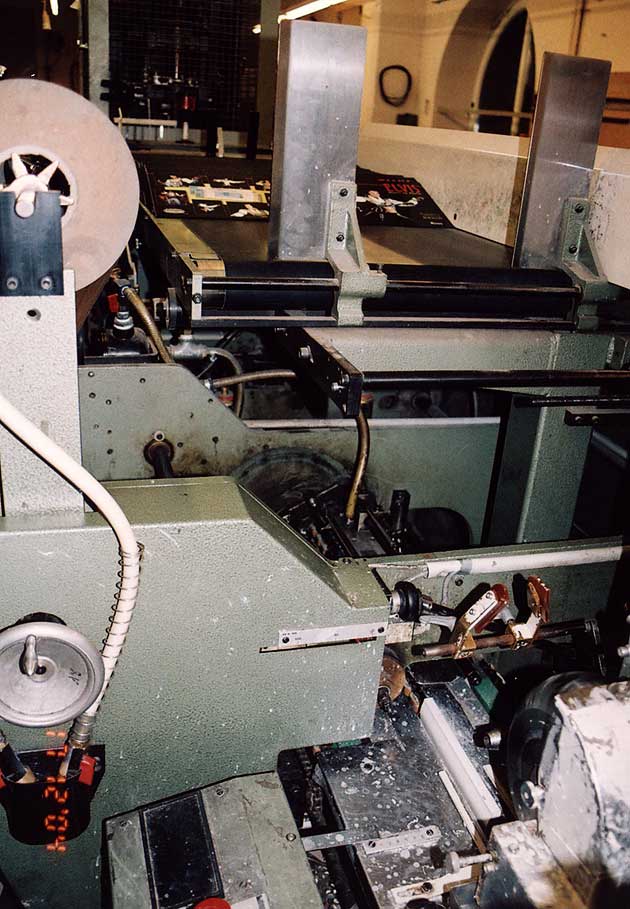

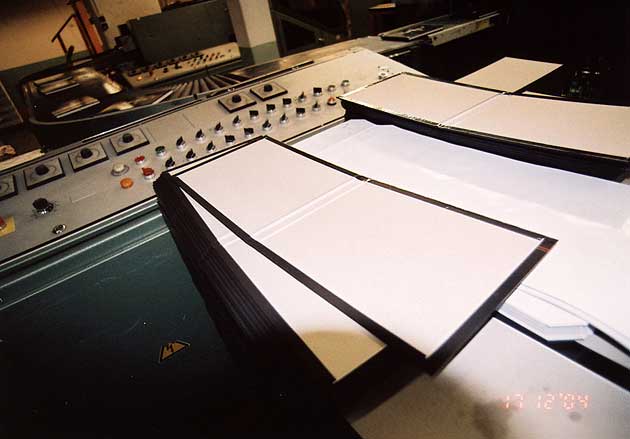

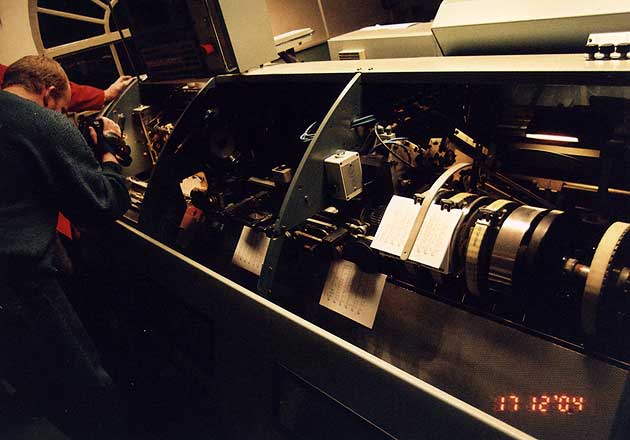

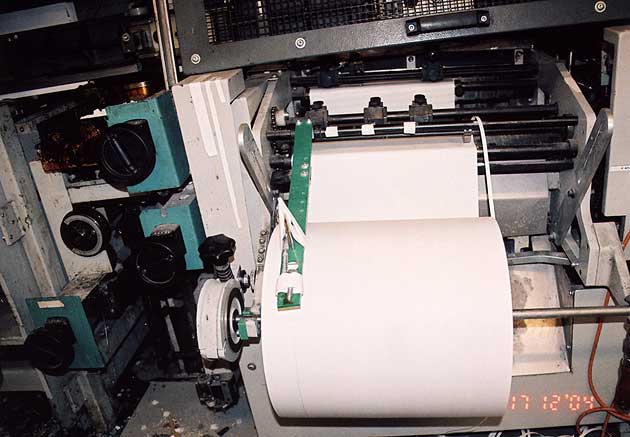

The completed sheets are being ejected at the end of the process by the machine and brought to the control desk.On the first sheet fine adjustments are being made. An expert is able to do changes manually, but the first controls are being made mechanically by the black box (left at the bottom). This way it is checked if the completed print accords to the pre-settings.

The completed sheets are being ejected at the end of the process by the machine and brought to the control desk.On the first sheet fine adjustments are being made. An expert is able to do changes manually, but the first controls are being made mechanically by the black box (left at the bottom). This way it is checked if the completed print accords to the pre-settings.

After another printing sweep the second version is being compared with the first print. Due to Mrs. Hainsch the red of the "Elvis: Born To Rock" writing doesn't only accords on all pages to the original red of Elvis's belt, but also that on all pictures, Elvis does not look pale-faced, but the red colourings also accord to human skin colourings.All the colours used in the book accord to the colours from Elvis' Jumpsuit. Due to the complete book is totally designed and high effort was made on every page to display the true colors.

After another printing sweep the second version is being compared with the first print. Due to Mrs. Hainsch the red of the "Elvis: Born To Rock" writing doesn't only accords on all pages to the original red of Elvis's belt, but also that on all pictures, Elvis does not look pale-faced, but the red colourings also accord to human skin colourings.All the colours used in the book accord to the colours from Elvis' Jumpsuit. Due to the complete book is totally designed and high effort was made on every page to display the true colors.

Markus Vogel and Claudia HainschThe experts and the owner of Dassel Druck GmbH at work.

Markus Vogel and Claudia HainschThe experts and the owner of Dassel Druck GmbH at work.

Mr. Vogel compares the prints with the proofs, lithographer Müller and Mrs. Hainsch check the prints again with the pre-settings. Mr Glasewald und Drinhaus discuss the quality and colourings of the test prints.The proofs are being consulted again for a direct comparison.

Mr. Vogel compares the prints with the proofs, lithographer Müller and Mrs. Hainsch check the prints again with the pre-settings. Mr Glasewald und Drinhaus discuss the quality and colourings of the test prints.The proofs are being consulted again for a direct comparison.

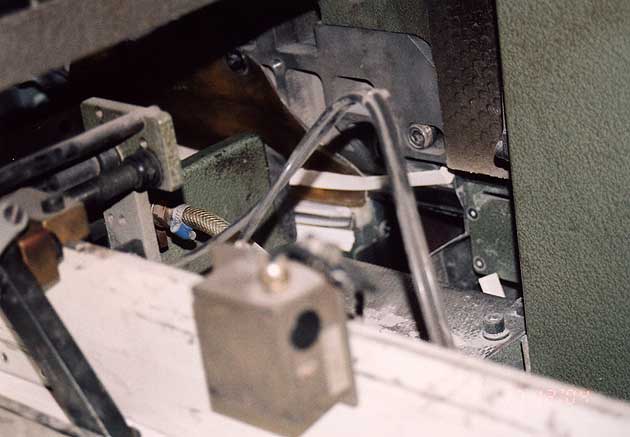

Herr Drinhaus controls the stratification of the completed sheets. One sheet contains 8 double-pages of the book.Most of the settings of the machine are adjustable by the desk; but some of them can only be done by hand.

Herr Drinhaus controls the stratification of the completed sheets. One sheet contains 8 double-pages of the book.Most of the settings of the machine are adjustable by the desk; but some of them can only be done by hand.

Claudia Hainsch and Mr. MüllerMr. Müller and Claudia Hainsch

Claudia Hainsch and Mr. MüllerMr. Müller and Claudia Hainsch

The dedicated employees talking shop. The values for the print are now verified so that no further adaptations will be necessary. Only when there are failures or in-process inspections a manual interference is necessary.Herr Drinhaus retains a sheet during the final printing process for control.

The dedicated employees talking shop. The values for the print are now verified so that no further adaptations will be necessary. Only when there are failures or in-process inspections a manual interference is necessary.Herr Drinhaus retains a sheet during the final printing process for control.

Page by page is going through the machine and it's all a matter of time, until the machine says: This was the last page to be printed.The producers hope that you liked the 2nd part of the special and want to thank the company Dassel Druck GmbH for their cooperation and participation in this Making of Special of "Elvis: Born To Rock".

Page by page is going through the machine and it's all a matter of time, until the machine says: This was the last page to be printed.The producers hope that you liked the 2nd part of the special and want to thank the company Dassel Druck GmbH for their cooperation and participation in this Making of Special of "Elvis: Born To Rock".

-

Making Of "Born To Rock" Part 3 - Bindery Images 1-18

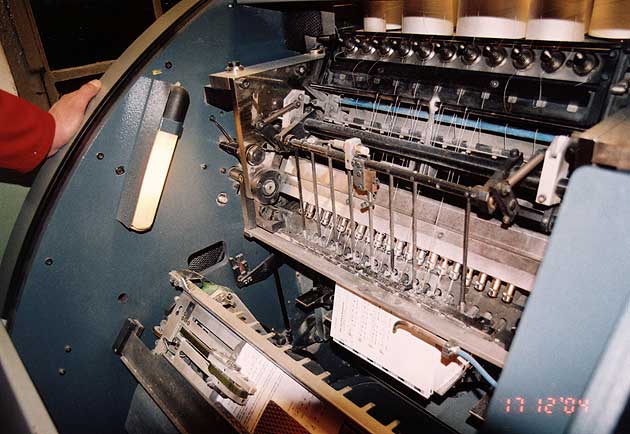

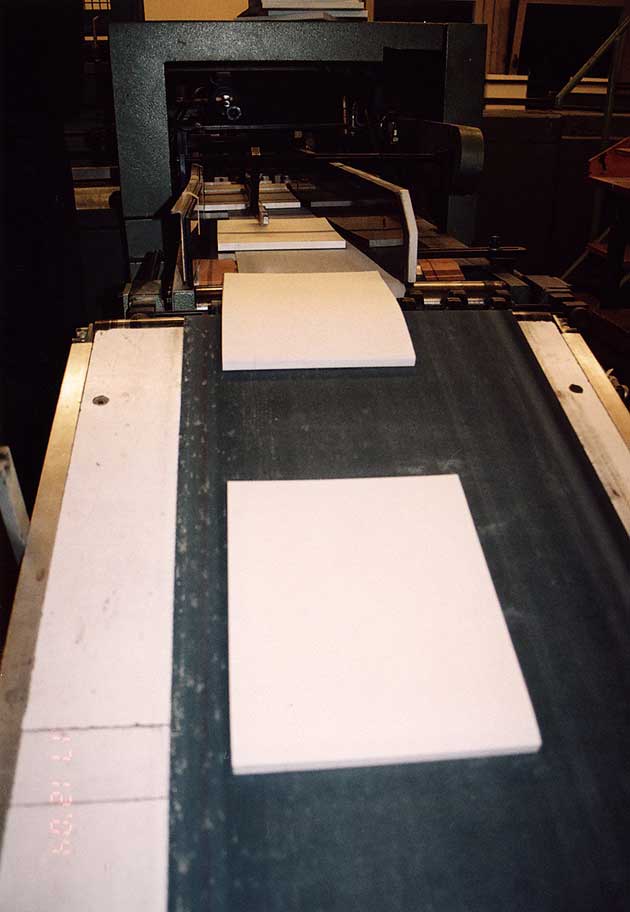

Having finished the actual printing jobs, last preparations are being made at the office to enable a smooth production flow at the bookbindery.An up to date tube- / round scannerThe completed sheets are arranged in a pile on pallets to be carried by trucks to the bookbindery.A last time the sheets are being examined by Mrs. Hainsch and Praytome. Only with the lens you are able to see the subtleties of the chosen paper and the used printing grid.The contentment in the faces mirrors the joy about the nearly finished product. Due to the great teamwork the initially discussed goals were reached: to set new standards concerning printing for Elvis publications to adjust design and layout to the content and to produce a full color book in a hardcover format with interesting information for the fans.In the next step the pallets with the finished sheets are being brought by truck to the bookbindery Gehring in Bielefeld, Germany.The entrance to the family business Gehring.In the first production step the sheets are being grooved and accumulated. For the right order is warranted the sheets have been marked at certain points by the printer so that after the piling a diagonal stripe has to develop. If it is not visible continuously the expert realizes immediately that the sorting process was incorrect.André Mester films every single production step while Mr. Kiel explains the procedures of the machines. In the following production step the sheets are being sewed to give the book a better steadiness. In opposition to the gluing it is avoided that later on, single pages peel away and fall out of the book.The complete production plant seems like a huge assembly line of a car factory. The employees have to adjust the machines before every production to the format of the upcoming project and then have to operate only in cases of failures.The single sheets are now sewed together. On long band-conveyors the sheets are being transported to the next machine.

-

Making Of "Born To Rock" Part 3 - Bindery Images 19-45

In the next step the sheets, which are sewed but still lightly out of their final position, are being laid planar together.In spite of the modern technology of this large firm a lot of busy hands are necessary to do the upcoming production steps.Because of a filter and roll system which becomes more and more narrow it is reached that the sheets don't cant and all single sheets are being aligned parallel.Again and again Mr. Kiel explains the production steps to the producers. Some procedures are only at the screen traceable, because special tailboards of the devices disable a direct view to the inside - safety has top priority.The sorted sheets are being glued with a piece of linen at the later spine so that a canting is no longer possible.In the end, the machine has made a big bunch of the several sheets. The bunches are being piled again to continue their way in a new production pant.The bunches are being additionally heated for the linen stripe hardens as fast as possible and that a better steadiness develops.The so called inboard book has respectively at the front and at the back an additional page with which it is later glued into the book cover.The inboard books are at the moment made from welted sheets. This means that there is no possibility yet to run over the pages of the book. To achieve this the following production step is necessary.First the inboard books are being stringed together …… to be piled later.The piles are being transported on a conveyer band into the cutting machine.In three steps the sheets are being trimmed on all edges but the spine so that from the sheets single pages emerge.The display shows a cutting rate of 34 bunches per minute.Deflection rollers are responsible for the inboard books being transported correctly adjusted into the next machine.

-

Making Of "Born To Rock" Part 3 - Bindery Images 46-62

From the cutting machine the bunch goes on into the production plant where the spine and the cover are being glued.Here the spine of the inboard book is being glued.After the gluing station of the spine the combine of the cover and the inboard book follows.Here you can see one of the many pallets where the blank covers are piled on.

From the cutting machine the bunch goes on into the production plant where the spine and the cover are being glued.Here the spine of the inboard book is being glued.After the gluing station of the spine the combine of the cover and the inboard book follows.Here you can see one of the many pallets where the blank covers are piled on.

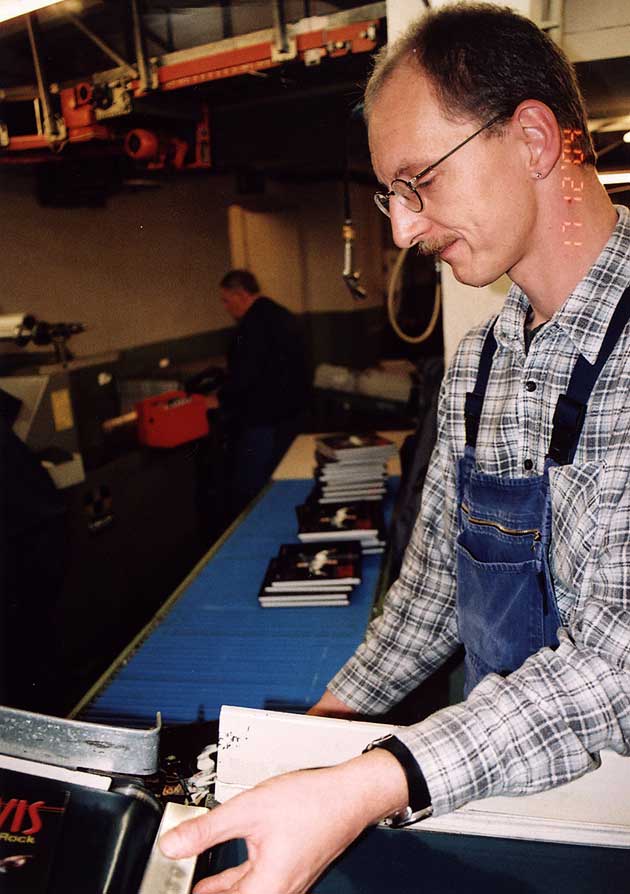

An employee of the company Gehring brings the next bunch of covers to the machine.The plain covers are being laid on the machine consistently so that on the grey side glue is being applied automatically and in the next step the combine of inboard book and cover can take place.Cover by cover is being retracted automatically.The inboard book is being brought up from the bottom and then laid on the glued cover. By compressed air and padded robot arms the book is being compressed to warrant an equal distribution of the glue.

An employee of the company Gehring brings the next bunch of covers to the machine.The plain covers are being laid on the machine consistently so that on the grey side glue is being applied automatically and in the next step the combine of inboard book and cover can take place.Cover by cover is being retracted automatically.The inboard book is being brought up from the bottom and then laid on the glued cover. By compressed air and padded robot arms the book is being compressed to warrant an equal distribution of the glue. -

Making Of "Born To Rock" Part 3 - Bindery Images 63-79

After the book was heated again for the glue drying out it has to weather a strict control by the skilled worker. Here every third book is being controlled for correct processing, cutting, gluing ect. …André Mester holds proudly one of the first copies of "Elvis: Born To Rock" in his hands!

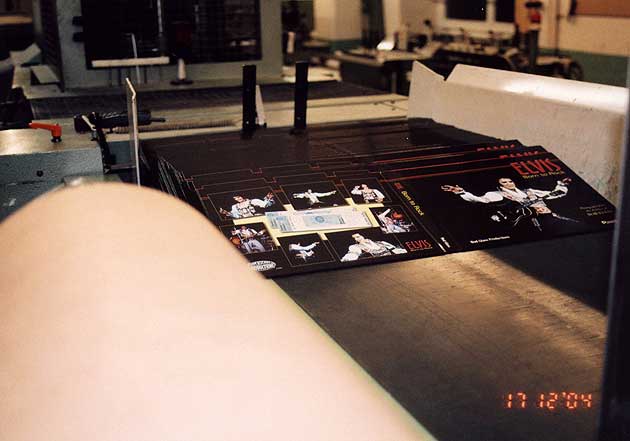

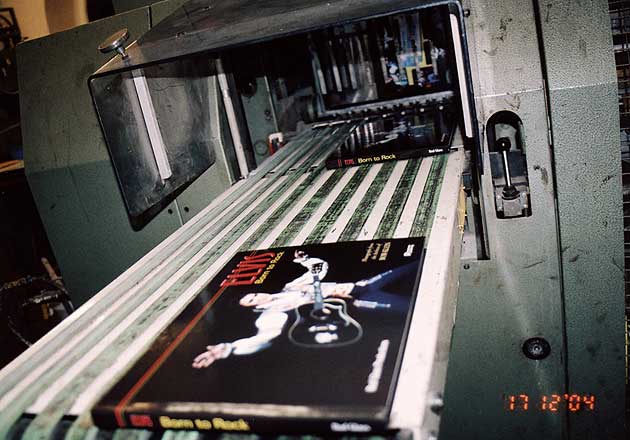

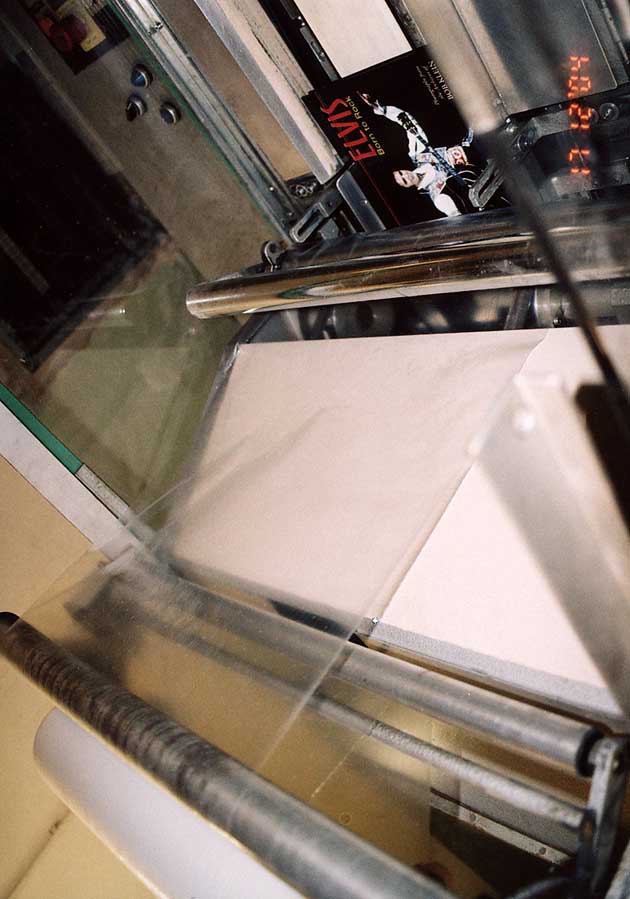

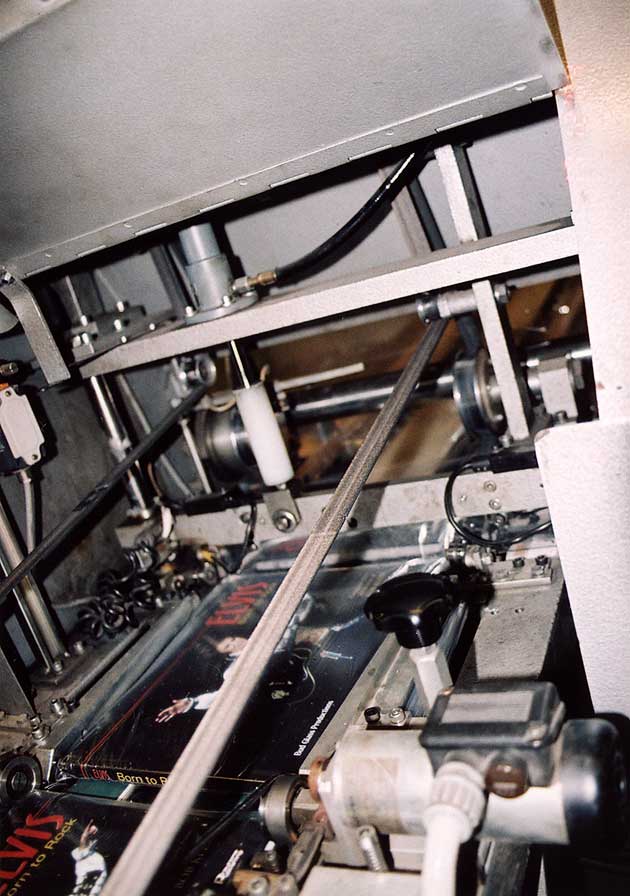

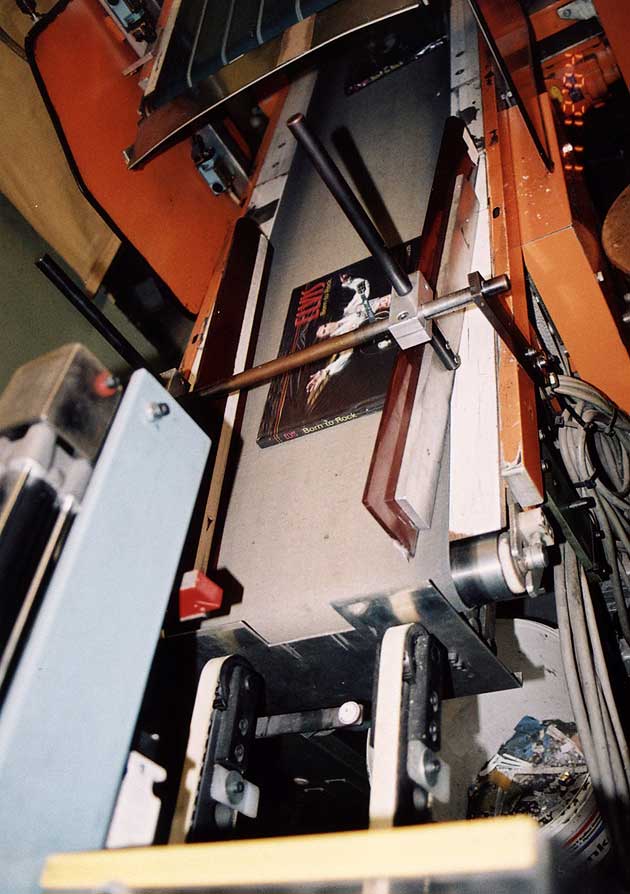

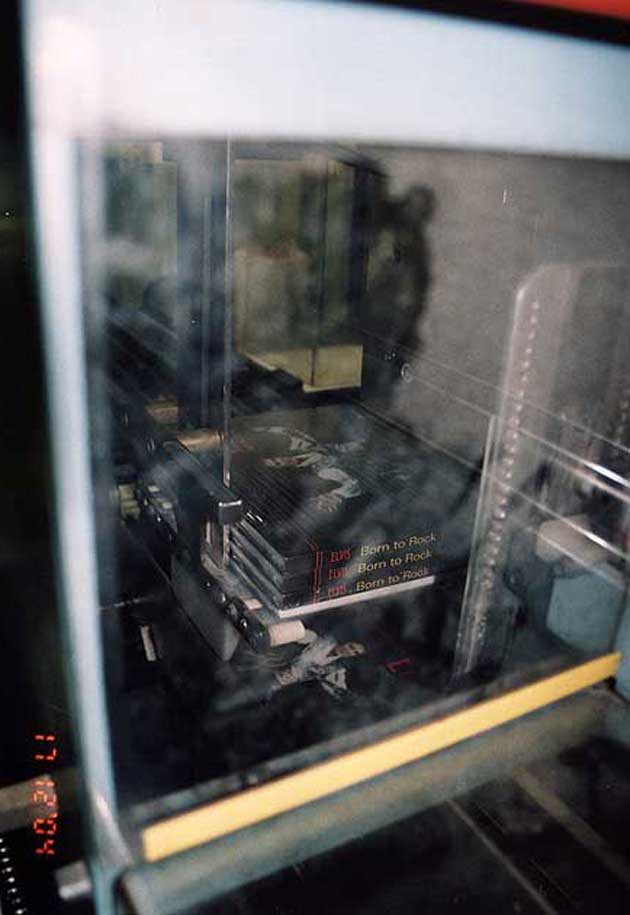

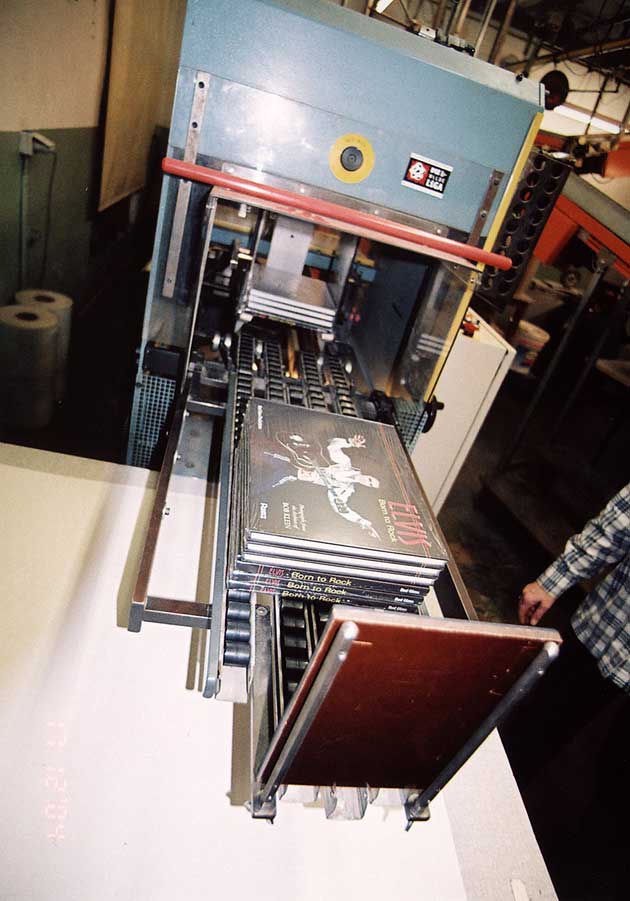

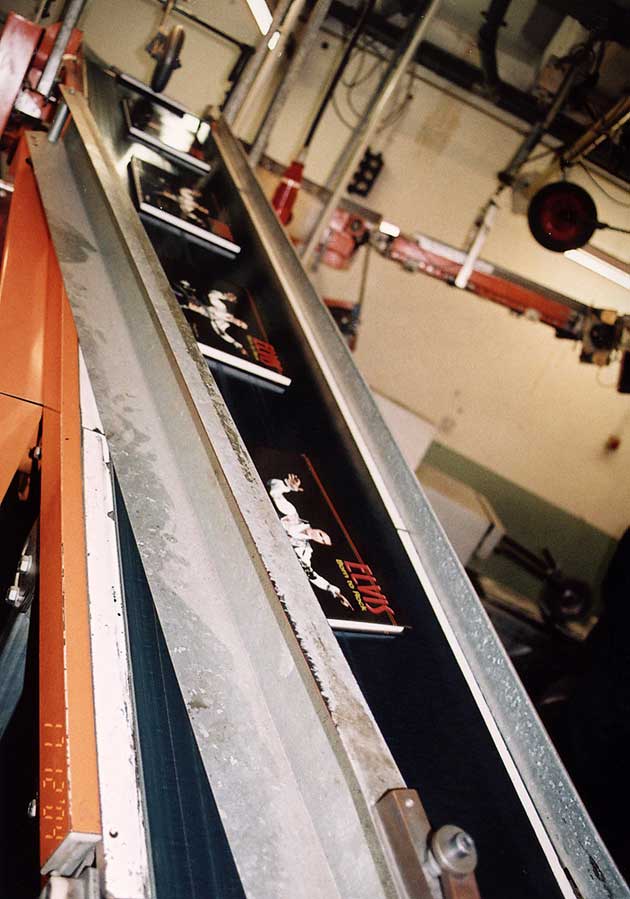

The conveyer band brings the completed books now to the lower level where the last production steps have to be done.Every single book is laid by hand on the conveyer band to be shrink-wrapped in cellophane.

The conveyer band brings the completed books now to the lower level where the last production steps have to be done.Every single book is laid by hand on the conveyer band to be shrink-wrapped in cellophane. The machine wraps the book with cellophane so that in the next step the foil shrinks by a new heating.After the shrinking process the books are piled to be stored on the pallets.The book has reached the last station of the conveyer band.Now the employees have to take the bunches by hand and pile them on the pallets.

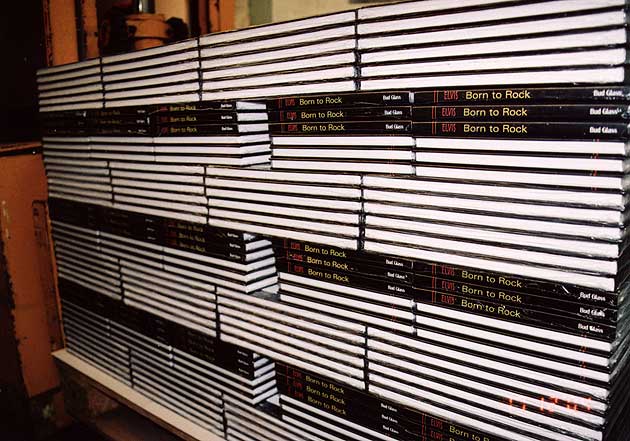

The machine wraps the book with cellophane so that in the next step the foil shrinks by a new heating.After the shrinking process the books are piled to be stored on the pallets.The book has reached the last station of the conveyer band.Now the employees have to take the bunches by hand and pile them on the pallets. The first pallet is piled. A lot will follow because the requests for "Elvis: Born To Rock" are huge and fans all over the world are waiting for their copies.With this last picture this "Making Of" Special has reached its end. The special was presented to you by "Praytome Publishing". But a very special highlight is already knocking on the door …

The first pallet is piled. A lot will follow because the requests for "Elvis: Born To Rock" are huge and fans all over the world are waiting for their copies.With this last picture this "Making Of" Special has reached its end. The special was presented to you by "Praytome Publishing". But a very special highlight is already knocking on the door …

Bud Glass himself, the author of the book "Elvis: Born To Rock" will give an account of his work about the development of the book. In that way you can be part of the creative and difficult work, from the idea to the conception until the completed design and content. You shouldn't miss that.